Parts constituent of old rifles

THUS STARTS PAGE 370 OF THE HANDBOOK OF ARTILLERIST EDITION OF “AN III”

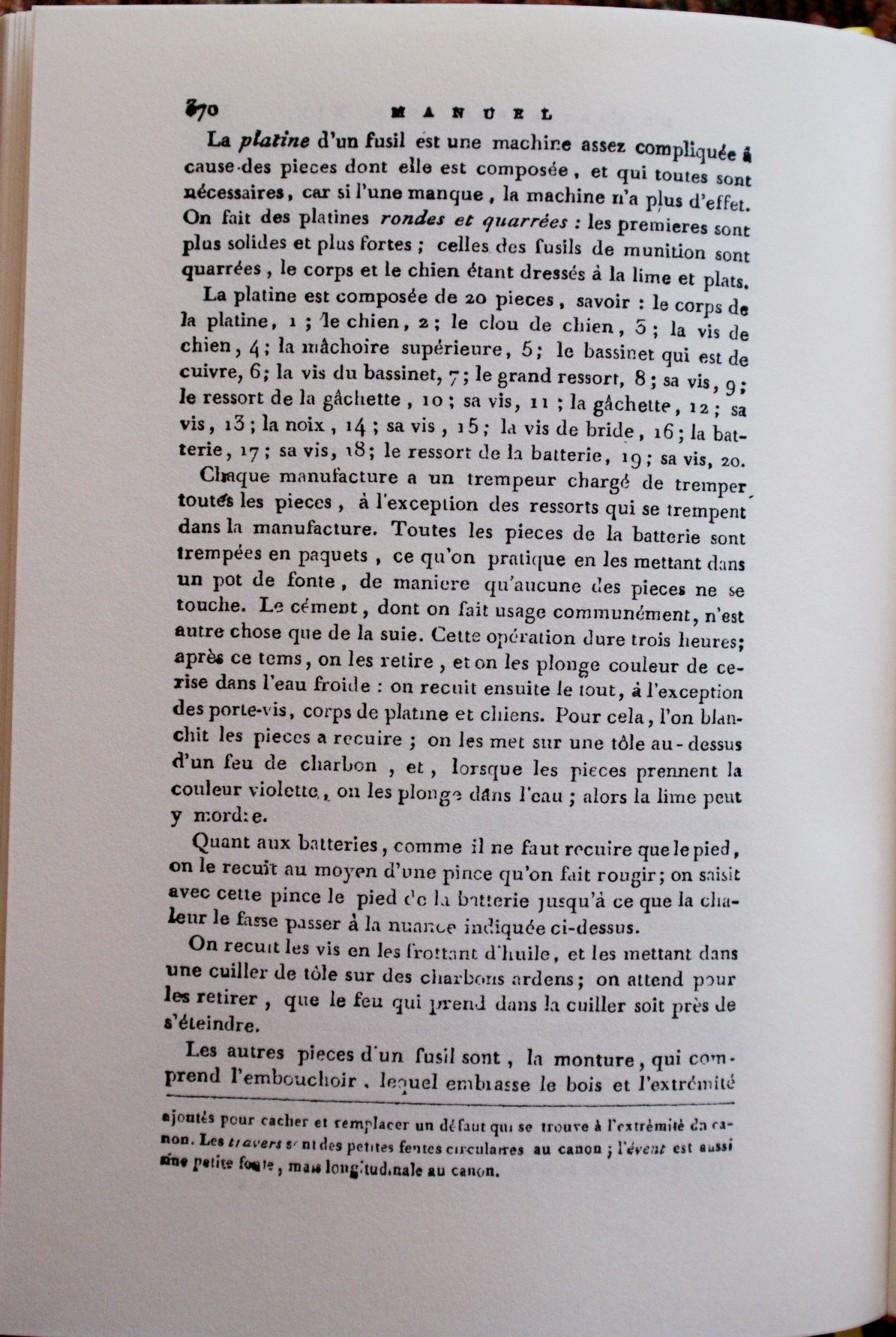

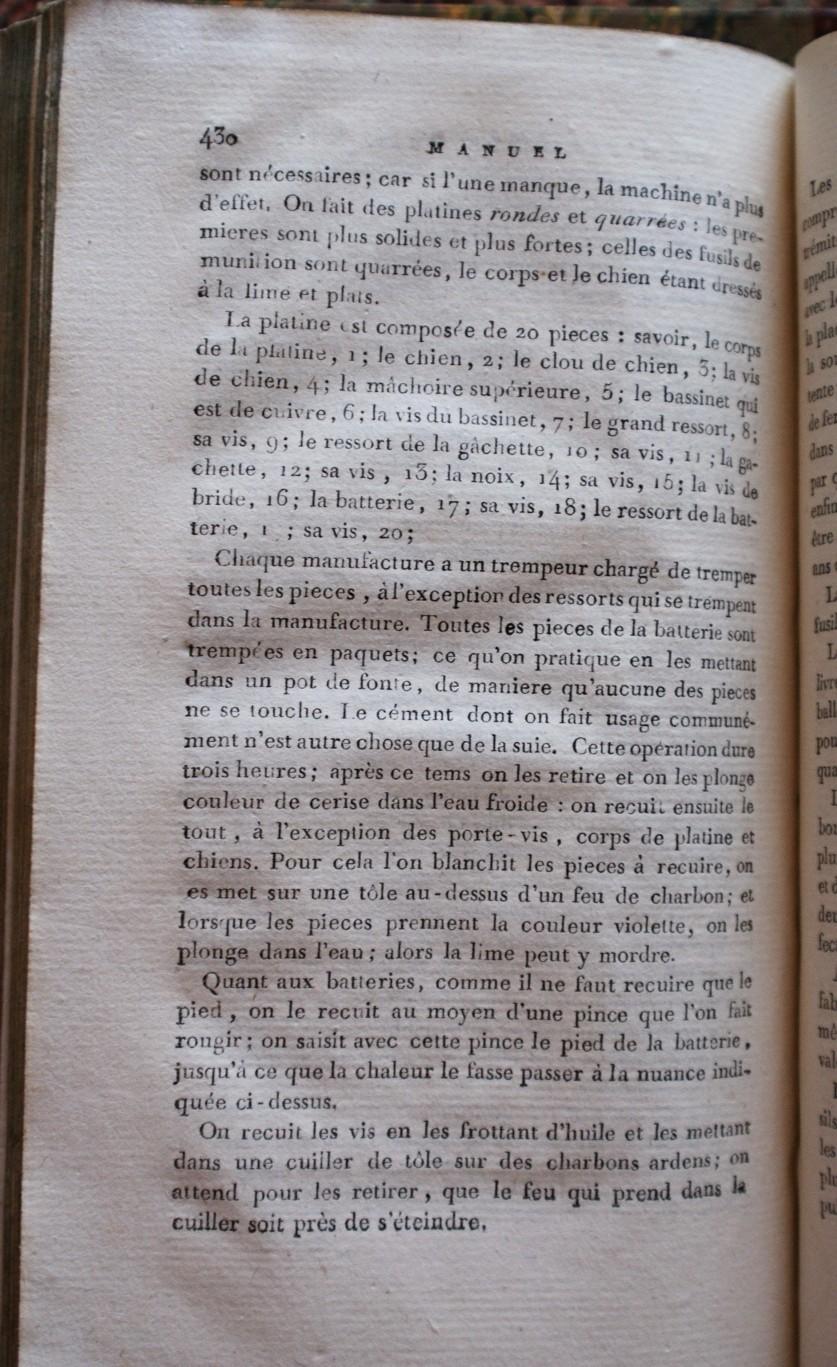

The lock of a rifle is a rather complicated machine because of the parts of which it is made up, and who all are necessary; because if it misses some, the machine does not have any more an effect. One makes round and square lock: the first are more solid and stronger; those of rifles of ammunition are square, the body and the hammer being with the file and dishes.

The lock is made up of 20 parts: to know the body of lock 1, hammer 2, the nail of hammer 3, the screw of hammer 4, the upper jaw 5, the small basin which is of copper 6, the screw of small basin 7, large spring 8, its screw 9, the spring of trigger 10, its screw 11, trigger 12, its screw 13, the nut 14, its screw 15, the screw of support 16, battery 17, its screw 18, the spring of battery 19, its screw 20.

RIFLE PRESENT IS N°1 OF the REVOLUTION WITH a LOCK AN IX & ONE MODIFICATION OF 1833 OF TULLE FOR SETTING TO the STANDARDS

DESCRIPTION OF THE LOCK SEEN OF ITS RIGHT SIDE

SIGHT INTERNS THIS ONE (Intern view of the lock)

DESCRIPTION OF EDITION OF “AN III”

Lock / Dismount spring / Moulds with balls / Draws flock and balls

SIGHT OF EDITION OF “AN II”

OPERATION OF THE LOCK

Lock with the 1st notch

Lock with the closed battery, hammer with the first notch

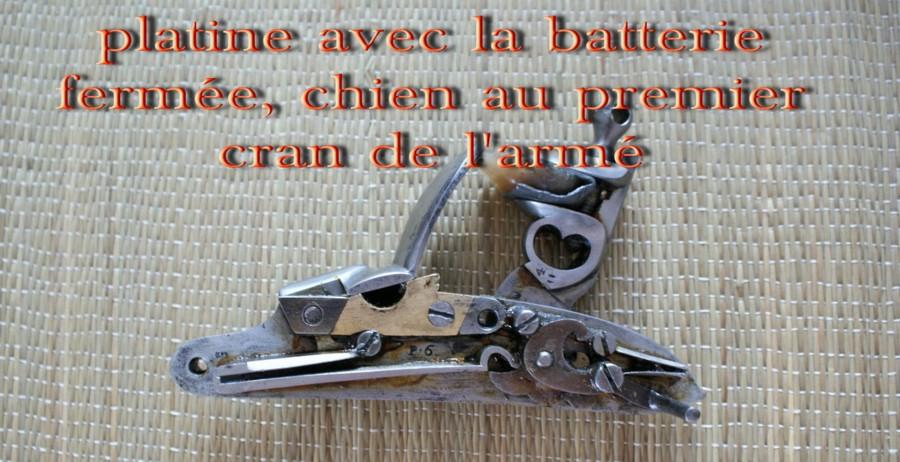

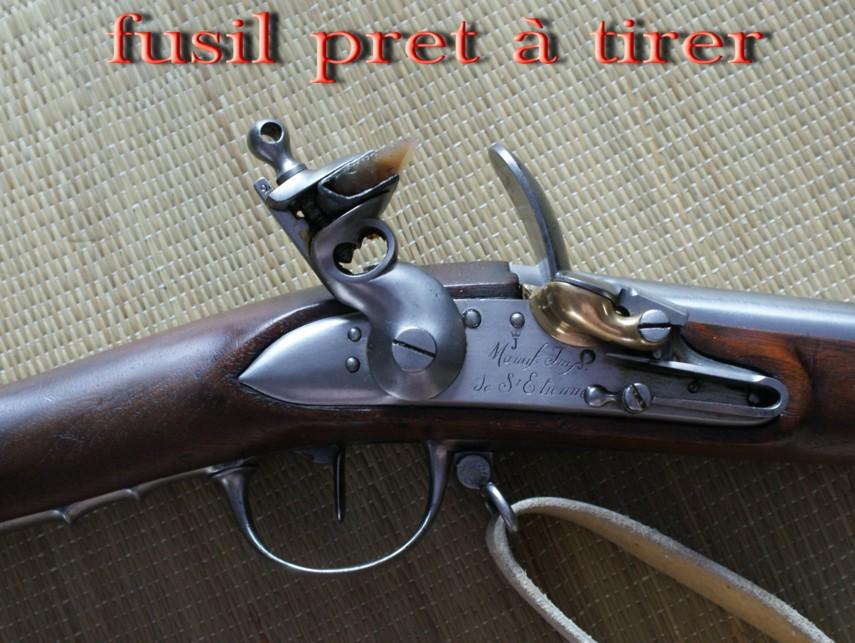

Rifle ready to shoot

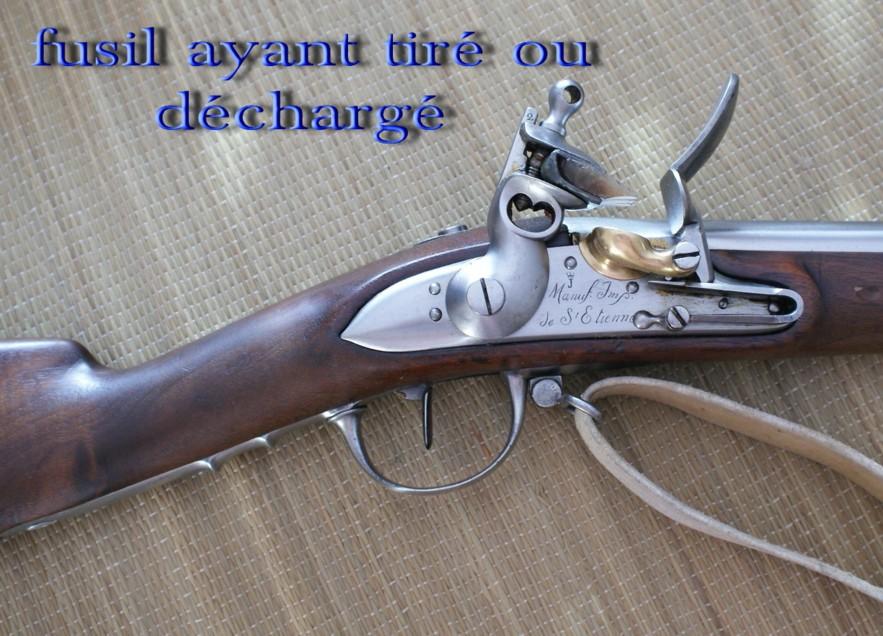

Rifle having shoot or discharged

In France, at the end of the XVIII century, there are 3 private manufactures which manufacture rifles of the army: *

MAUBEUGES, CHARLEVILLE and SAINT-ETIENNE.

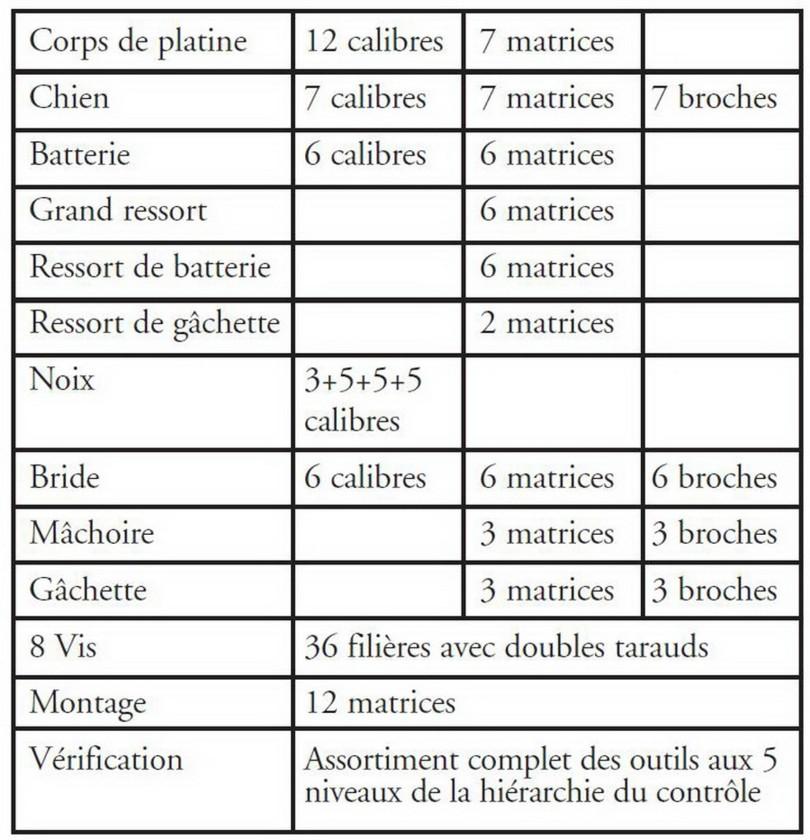

The bursting of these centers of manufacture and their private management don’t facilitate the military action of the persons in charge to make evolve the methods. The manufacture of a traditional rifle is worked with the forging mill and the file starting from steel and iron blades which undergo many heats, to forge a barrel asks 63 of its heats (Weldings) on a pin by several hammerings on heated iron has white. Then the barrel is drilled by the passage of several drills. The other principal part of rifle is the lock, its design asks for also precision of manufacture. New techniques of design were developed by DESCHAMPS since 1723, it invented this technology to limit the work of completion to the file on this principal part; its concept is the use of parts forged by hot stamping, the use of gauge of checking at each time of manufacture in order to obtain identical dimensions for each produced part.

The use of these gauges and matrices of forging mills limit the rejects and increase the production and the quality of its parts.

The division of the labor in fifteen stations, is sixty twelve workmen, who manufactured six thousand seven hundred and twenty locks per annum. Their tools cost eight hundred and eight livres (French money) (tournaments). However a lock costing 3 livres, if the tools were renewed every year, that did not increase the production cost that by 4% - the true problem of this production was with the deceleration of the production and rejects.

Table of tools to produce a lock of rifle of ammunition

NAMES GIVE TO THE VARIOUS PARTS OF THE WEAPON

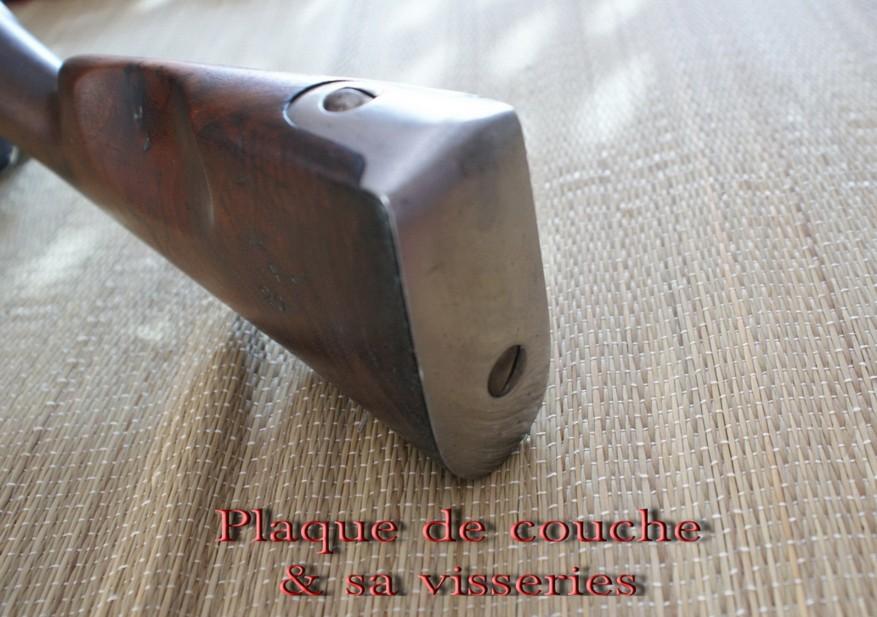

Buttplate and his screw

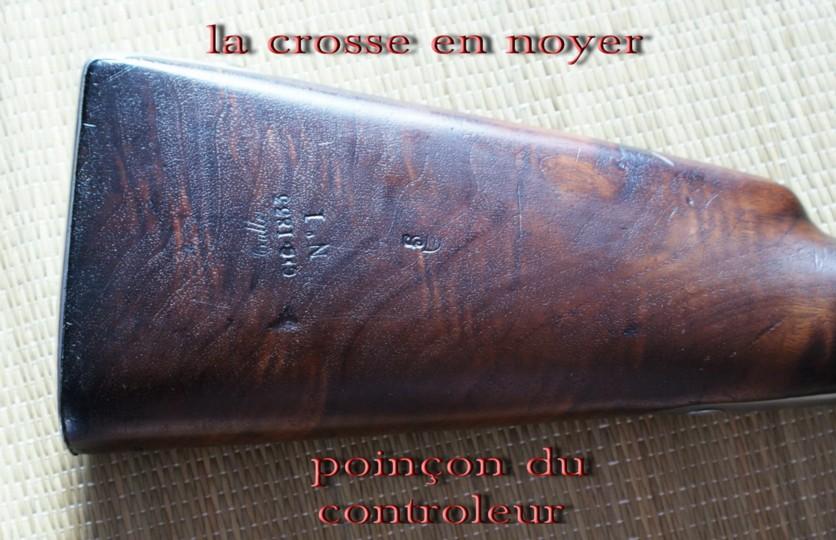

Action in walnut

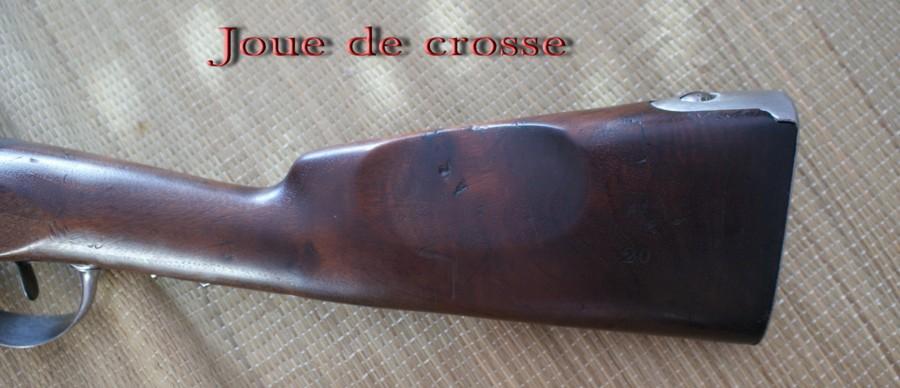

Cheekpiece

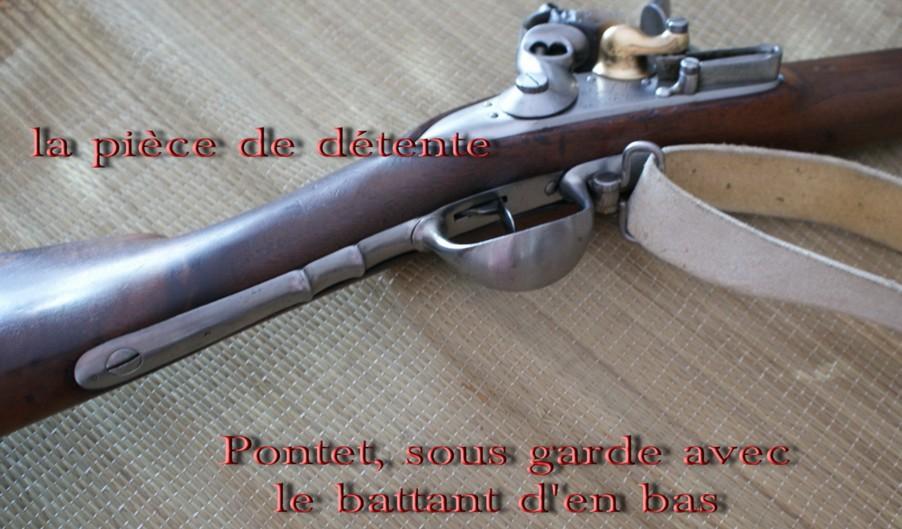

Trigger

Trigger guard

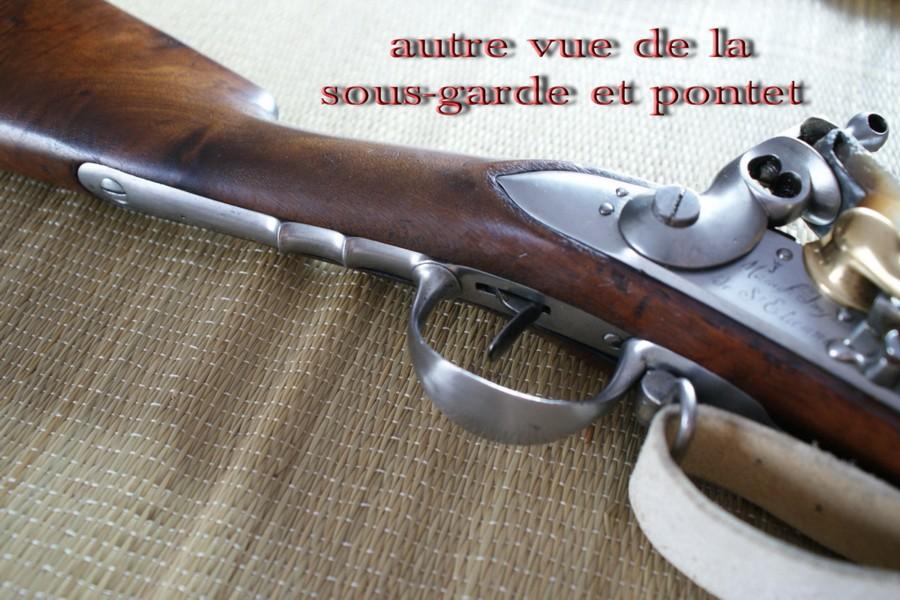

Another view of trigger guard

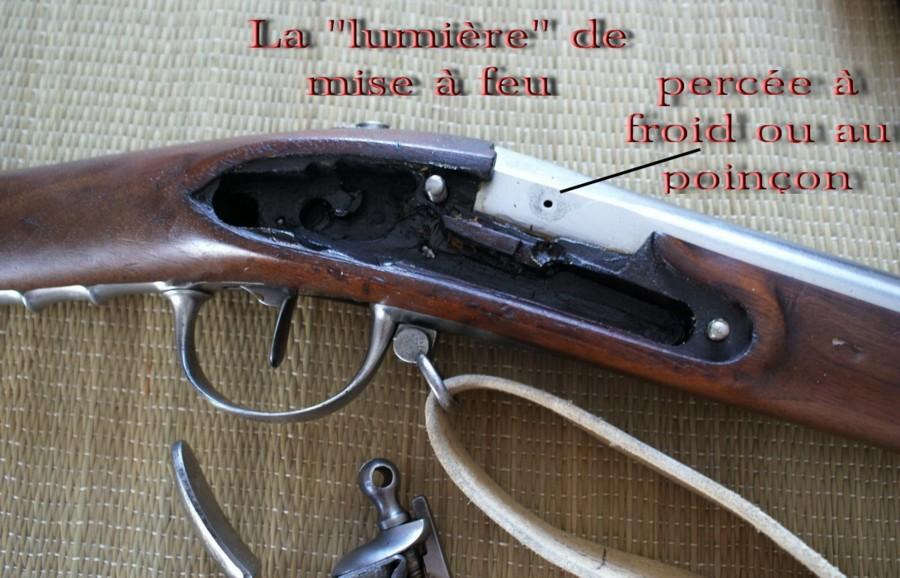

Hole of fire

LOCK WITH “RETROUSSI” OF BATTERIES Model 1777 front view

Same internal sight

Realized with the assistance of old documents.

Technical support: “@lain of www.littlegun.be”.

Private credit photographs & drawings @glt08 reserved ww.littlegun.be

copyright ww.littlegun.be - @glt08